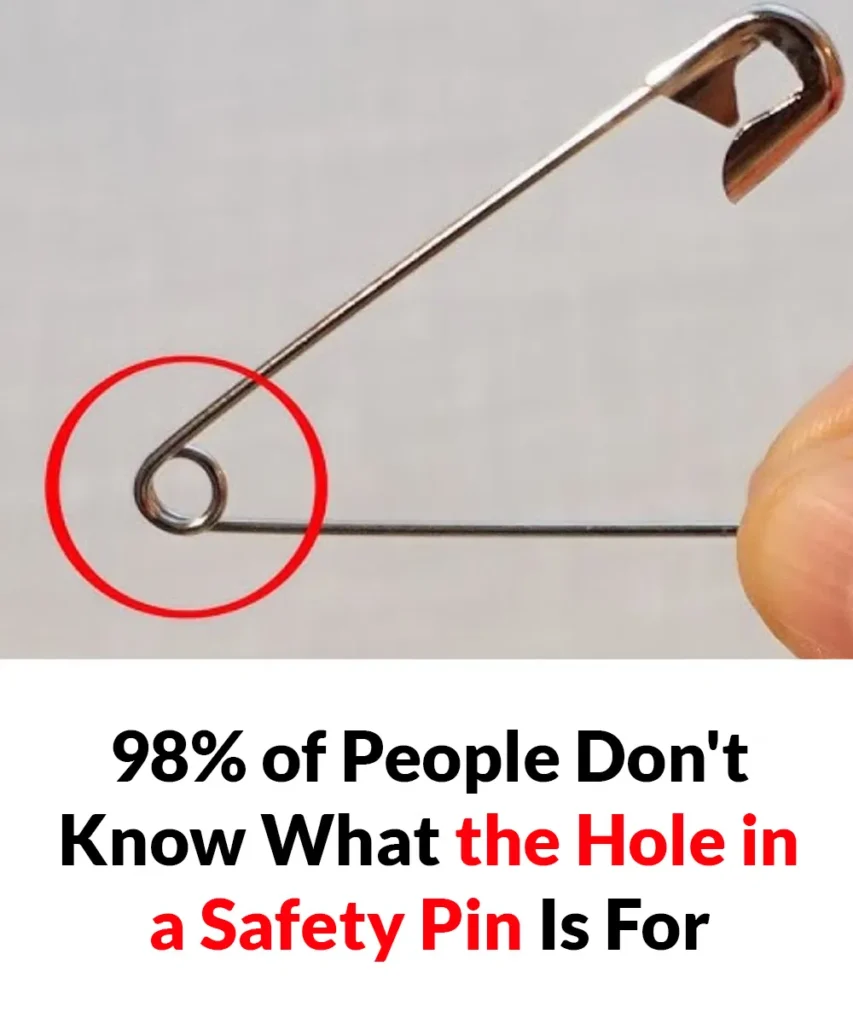

What’s the Purpose of That Tiny Hole in a Safety Pin?

Safety pins are humble yet ingenious inventions that have served humankind for over a century. At first glance, they seem simple—a clasping pin designed to fasten fabric or materials together. But if you inspect one closely, you might notice a curious detail: a tiny hole often located at the end of the coil or near the clasp. What is the purpose of this barely noticeable feature? Why does such a small hole matter? Let’s explore the design significance behind it and even walk through how one might create it in the manufacturing process.

Understanding the Anatomy of a Safety Pin

Before diving into the purpose of the hole, let’s quickly review the parts of a safety pin:

- Pointed Pin (Needle): The sharp end used to pierce fabric.

- Spring Coil: The twisted portion that stores energy, allowing the pin to open and close securely.

- Clasp/Guard: The cap that covers the sharp tip to prevent injury.

- Tiny Hole: The often-overlooked small hole near or inside the clasp.

What’s the Purpose of the Tiny Hole?

Though small, this hole serves important manufacturing and practical purposes:

1. Manufacturing Alignment

During mass production, safety pins are rapidly assembled by machines. The tiny hole allows automated equipment to align, hold, and manipulate the pin accurately during critical stages of manufacturing such as:

- Forming the spring coil.

- Positioning the clasp.

- Cutting and shaping the sharp point.

2. Quality Control and Inspection

The hole can also serve as a checkpoint for mechanical inspection systems. High-speed cameras or sensors may use the hole to verify correct orientation or ensure a pin is structurally sound before packaging.

3. Assembly Rivet or Pin Point

In some designs, the hole serves as an anchor point for riveting or for attaching the clasp firmly to the coil. It prevents slippage and ensures the sharp point remains protected when closed.

4. Optional Threading Feature

In some craft or sewing applications, the hole can be used to thread a thin string or tag, allowing the pin to serve as a tag-holder or badge fastener.

How Is the Tiny Hole Made? Step-by-Step Method

Creating a safety pin, including its small hole, involves a precise series of mechanical steps in a factory setting. Here’s how it typically happens:

Step 1: Wire Preparation

- Material: Stainless steel or brass wire is fed from spools into the machine.

- Cutting: The wire is cut into pre-determined lengths, usually around 2–3 inches depending on the pin size.

Step 2: Coiling and Shaping

- The wire is bent to form a coil on one end. This acts as the spring mechanism.

- This coil allows flexibility and tension, ensuring the pin stays closed securely.